Join the Baileigh Army!

Sign up for our newsletter and stay in the know! Get exclusive access to the latest product updates, special offers, classes and events delivered right to your inbox.

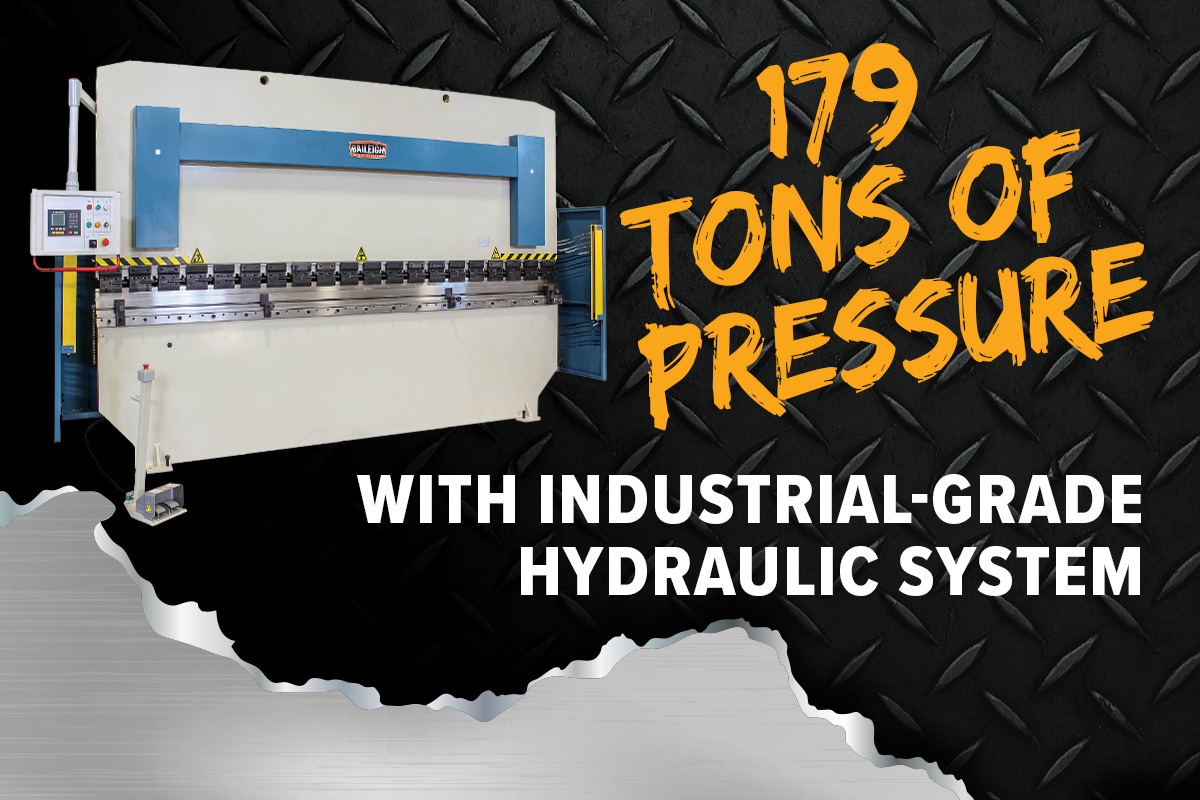

High-Capacity CNC Hydraulic Press Brake: The Baileigh BP-17913CNC Press Brake is a heavy-duty 179 ton hydraulic CNC press brake built for large-scale metal forming and fabrication shops. With a 13-foot (157″) bending bed, this machine is engineered to handle large panels and heavy parts with precision and consistency.

Precision Controls & Rugged Construction: Featuring 2-axis Estun E21 CNC control with programmable functionality, the BP-17913CNC lets operators store and recall multiple bend sequences for efficient and repeatable production. The fully welded, stress-relieved steel frame and industrial-grade hydraulic drive system with premium components deliver smooth, balanced bending performance job after job.

Order Yours Today: Call 920-684-4990 to speak with a Baileigh specialist for pricing, availability, and to place your order today.

Service & Support

Assistance for a smooth shopping experience

Operation Manuals

Learn the machine's application and limitations

Product Registration

Register your product to get fully warranty benefits

Warranty & Parts

Learn more about what is covered by our warranties

This product has not been reviewed yet.

* - indicates required fields.